Sale

Alternative Products

ITEM CODE:

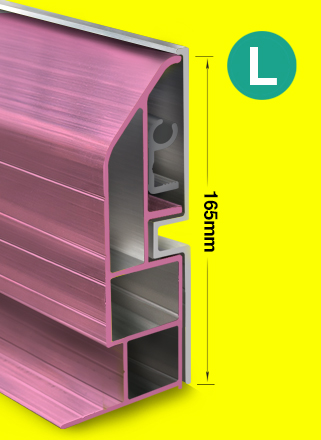

SA 1645K

SA N2-4 LED Neon Flex 24V Blue (9.6W/M)

In stock

| Range | Price |

|---|---|

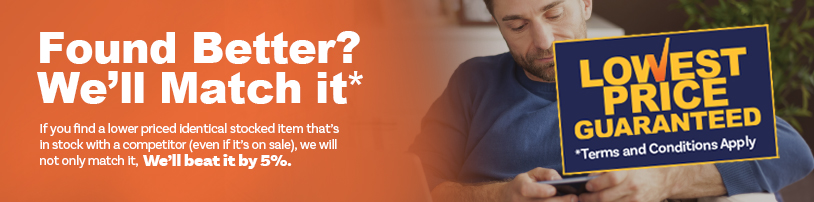

| From | $19.73 $26.8 / metre |

$86.30 – $535.94 Excl. GST

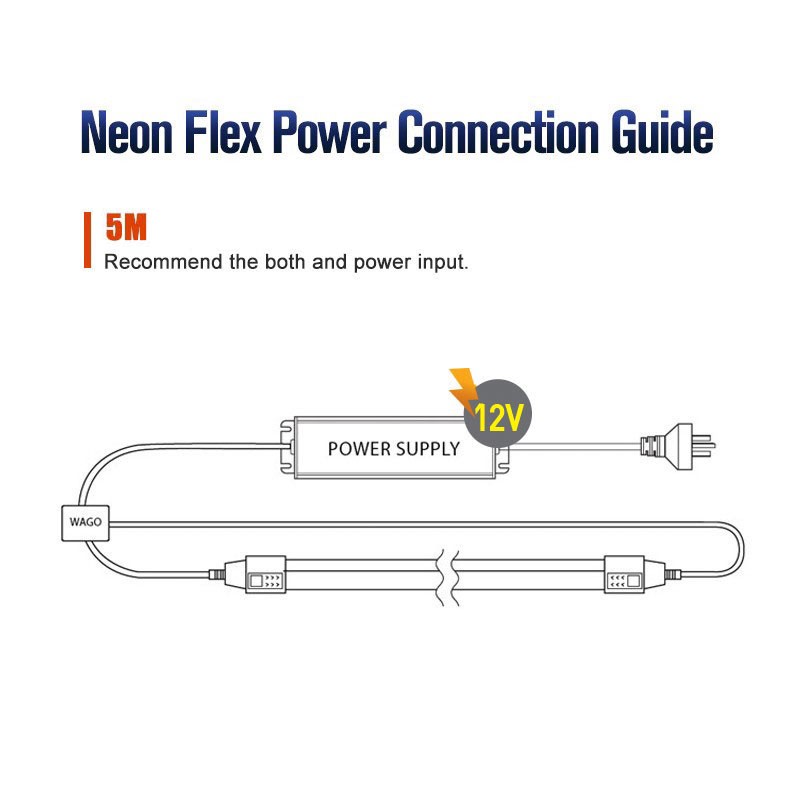

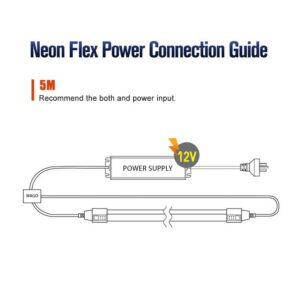

Find suitable power supplier ? (click)

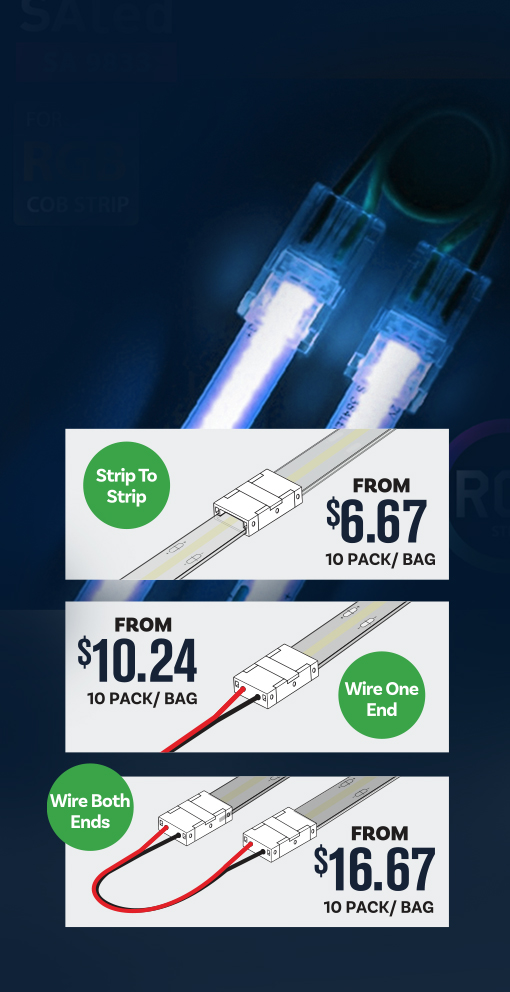

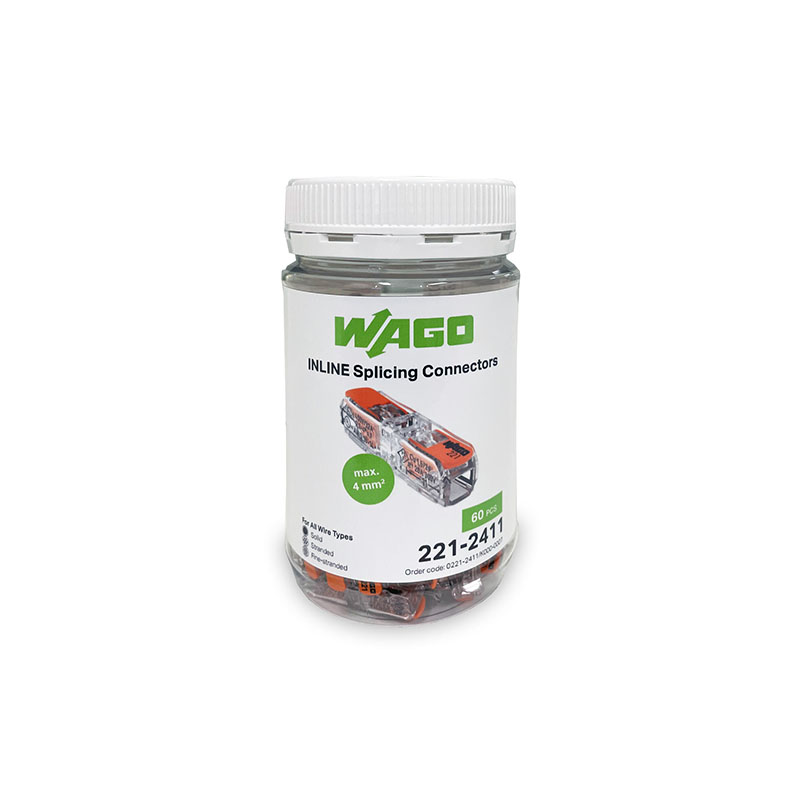

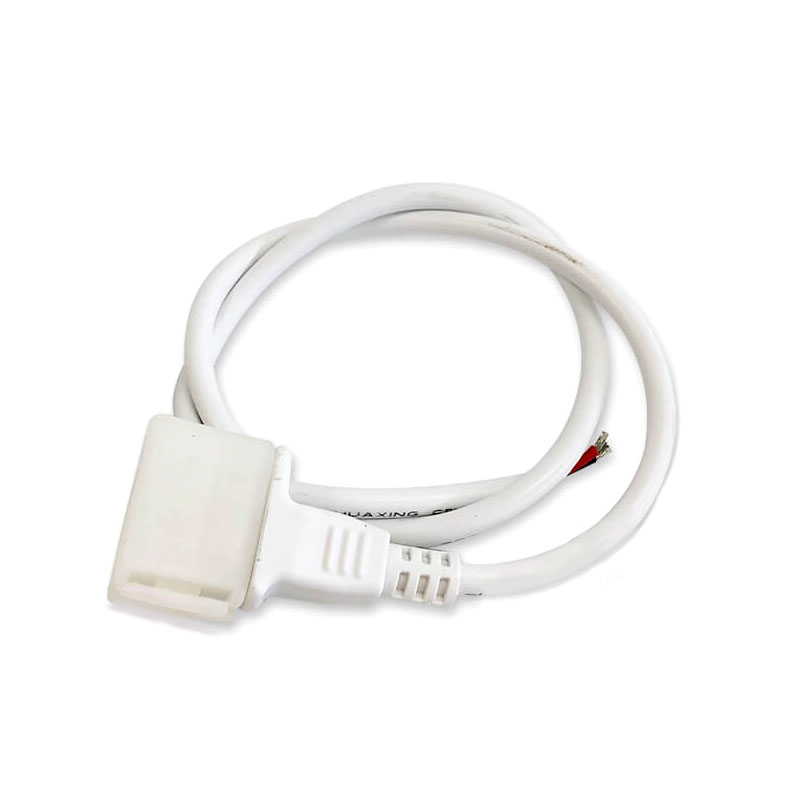

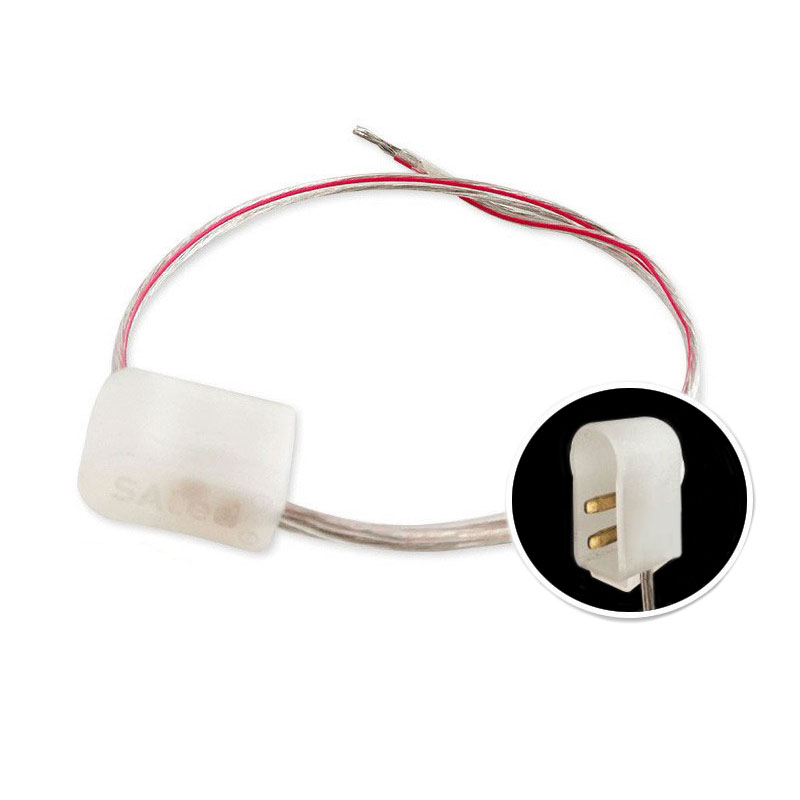

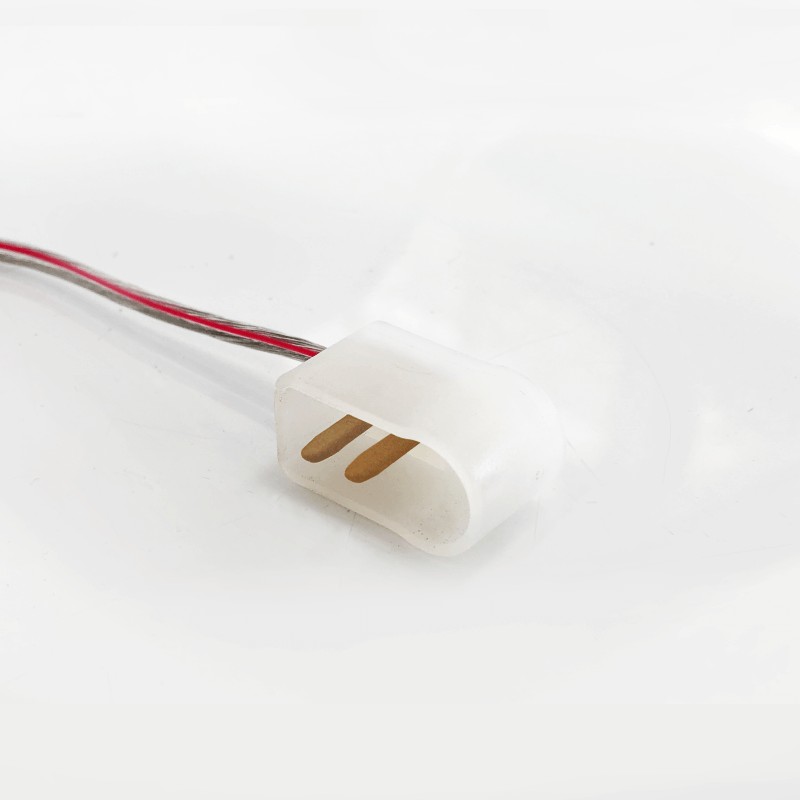

Need to buy accessories as well ? (click)

Need to buy accessories as well ? (click)